#IT infrastructure cost reduction techniques

Explore tagged Tumblr posts

Text

As we step into 2024, the economic scenario further emphasizes the need for effective strategies to reduce infrastructure costs in IT. In this blog, we’ll explore proven methodologies to achieve a 15 to 20% cost advantage over competitors, focusing on the crucial aspect of reducing IT infrastructure costs.

#Reduce IT Infrastructure Costs#reduce infrastructure costs#reduce infrastructure costs in IT#Cloud applications development company#reduce it infrastructure costs US#reduce development time#IT Infrastructure#IT standardisation#IT infrastructure cost reduction techniques

0 notes

Text

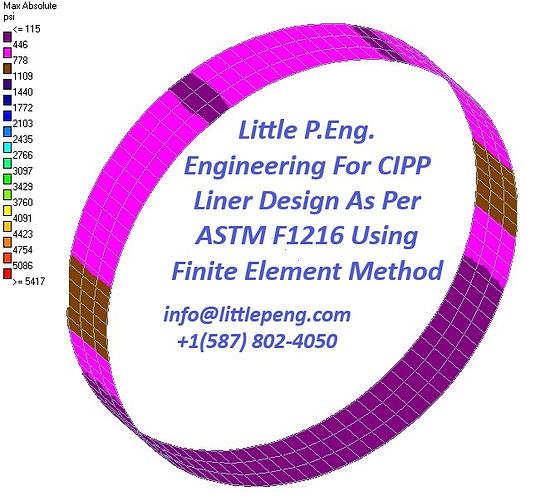

Little P.Eng. Engineering For CIPP Liner Design As Per ASTM F1216 Using Finite Element Method

In the realm of civil engineering, the rehabilitation of pipelines is a critical task that ensures the longevity and safety of underground infrastructure. One of the most innovative and efficient methods for pipeline rehabilitation is Cured-in-Place Pipe (CIPP) lining. This technique not only offers a less intrusive alternative to traditional pipeline repair but also significantly reduces the environmental impact and cost associated with excavation. Little P.Eng. Engineering, a pioneering firm in the engineering consultancy landscape, has taken strides in optimizing CIPP liner design to comply with ASTM F1216 standards through the application of the Finite Element Method (FEM).

Understanding ASTM F1216 and its Significance

ASTM F1216 is a standard that outlines the procedures for rehabilitating existing pipelines using the CIPP method. This standard is critical as it provides guidelines for the design, installation, and testing of CIPP liners, ensuring that rehabilitated pipelines meet specific safety and performance criteria. Compliance with ASTM F1216 is essential for any project involving CIPP lining, as it not only guarantees the structural integrity of the rehabilitated pipeline but also its longevity.

Little P.Eng. Engineering's Approach to CIPP Liner Design

Little P.Eng. Engineering has embraced the challenges of CIPP liner design by leveraging the Finite Element Method (FEM), a sophisticated computational technique that simulates how materials behave under various conditions. FEM allows engineers to model the complex interactions between the CIPP liner and the host pipe, taking into account factors such as material properties, external loads, and environmental conditions. By using FEM, Little P.Eng. Engineering can predict the performance of CIPP liners with high accuracy, ensuring that designs are not only compliant with ASTM F1216 but also optimized for durability and efficiency.

The Role of Finite Element Method in Ensuring Compliance and Optimization

The Finite Element Method plays a pivotal role in Little P.Eng. Engineering's design process by providing a detailed analysis of stress distribution, deformation, and potential failure points within the CIPP liner. This detailed analysis is crucial for two main reasons:

Compliance with ASTM F1216: FEM analysis helps ensure that the designed CIPP liner can withstand the intended service life under varying conditions, as stipulated by ASTM F1216. This includes assessing the liner's ability to handle internal pressures, ground movement, and other environmental factors without compromising its structural integrity.

Optimization of Design: Beyond compliance, FEM enables Little P.Eng. Engineering to optimize the thickness, material composition, and installation parameters of CIPP liners. This optimization not only reduces material costs but also minimizes the risk of over-engineering, ensuring that resources are used efficiently without sacrificing performance.

Case Studies and Success Stories

Conclusion

The innovative approach of Little P.Eng. Engineering to CIPP liner design, grounded in the rigorous application of the Finite Element Method and adherence to ASTM F1216 standards, represents a significant advancement in pipeline rehabilitation technology. This method not only ensures the structural integrity and longevity of CIPP liners but also exemplifies how engineering innovation can lead to more sustainable and cost-effective infrastructure solutions. As the demand for efficient and environmentally friendly rehabilitation methods grows, the work of Little P.Eng. Engineering in this field is set to become increasingly important, paving the way for future advancements in civil engineering practices.

Read More:

Innovating Pipeline Rehabilitation: Pipe CIPP Lining Engineering Design Services as per ASTM F1216

Pipeline Rehabilitation Engineering Design Services as per ASTM F1216 Using CIPP and PVC

Little P.Eng. Engineering For CIPP Liner Design As Per ASTM F1216 Using Finite Element Method

Revolutionizing Pipe Rehabilitation: Little P.Eng. Engineering's Mastery of CIPP Liner Design via Finite Element Method in Accordance with ASTM F1216

Tags:

Little P.Eng. Engineering

ASTM F1216

structural integrity

design optimization

engineering innovation

material properties

Finite Element Method

underground infrastructure

performance prediction

industry guidelines

CIPP liner design

material optimization

infrastructure longevity

safety criteria

environmental impact

maintenance cost reduction

pipeline rehabilitation

simulation techniques

performance criteria

durability assessment

compliance standards

computational modeling

non-invasive repair methods

failure point identification

sustainable solutions

installation parameters

stress distribution analysis

external loads

civil engineering practices

cost reduction

Engineering Services

•

Pipe Rehabilitation

Located in Calgary, Alberta; Vancouver, BC; Toronto, Ontario; Edmonton, Alberta; Houston Texas; Torrance, California; El Segundo, CA; Manhattan Beach, CA; Concord, CA; We offer our engineering consultancy services across Canada and United States. Meena Rezkallah.

#Little P.Eng. Engineering#ASTM F1216#structural integrity#design optimization#engineering innovation#material properties#Finite Element Method#underground infrastructure#performance prediction#industry guidelines#CIPP liner design#material optimization#infrastructure longevity#safety criteria#environmental impact#maintenance cost reduction#pipeline rehabilitation#simulation techniques#performance criteria#durability assessment#compliance standards#computational modeling#non-invasive repair methods#failure point identification#sustainable solutions#installation parameters#stress distribution analysis#external loads#civil engineering practices#cost reduction

0 notes

Text

Why Should Organizations Choose RPA Managed Services Over In-House Automation?

In the current business world, time is a very valuable resource, and the work flow depends on efficiency. Automation, especially through Robotics Process Automation, has proven to become more functional in enabling a reduction of excessive human interventions. Even if it is wise to develop an in-house automation team, there are key benefits associated with managed RPA services that explain why organizations should seek the help of the latter.

Here's why more and more organizations are choosing external expertise for their RPA needs:

Faster Implementation and Time-to-Value: Developing an effective Centre of Excellence for RPA services demands a substantial amount of time, and a lot of effort goes into recruitment activities, training, and infrastructure development. The implementation of IT management services is more efficient with MSPs as they already have the knowledge and tools in place, so it is faster to gain a return on investment. According to data gathered from numerous industries, first-order automation gains through engaging managed services run approximately 40% better than those achieved by setting up in-house centers of excellence.

Access to Specialized Skills and Experience: Today RPA services is a rapidly developing industry. Managed service providers employ teams of certified professionals with diverse experience across various industries and RPA service platforms. They also provide access to best practice ideas, new and improved techniques, and niche solutions for particular types of business, aspects which cannot easily or inexpensively be duplicated in-house. Data collected using the current survey shows that 65% of the companies are outsourcing RPA with a primary motivation to access specialized skills.

Cost Efficiency and Predictable Expenses: On the other hand, although in-house automation becomes cheaper in the long run, the upfront cost of personnel hiring and training, software purchase, and maintenance is considerably high and variable. Managed services are given on a subscription basis, and this factor eliminates the element of uncertainty, resulting in lower costs. Researches also indicate that outsourcing of RPA services may make the costs to be decreased by about 30% lower than if it was to be done internally.

Scalability and Flexibility: Business needs fluctuate. Managed RPA services permit the demand for capacity for automation to be adjusted according to the requirements, and is not restricted just like the hiring of employees or purchasing more equipment that is required for permanent automation services. This is important for meeting the ever-changing market needs and the growth of the business. There is information that organizations cooperating with managed services enjoy 25% more freedom in scaling up their automation processes.

Focus on Core Business Activities: Outsourcing an RPA project creates the need for an in-house in-IT team to run and maintain the project away from its core business functions. For this reason, when one hires the services of an MSP, internal teams are relieved of handling tasks that can otherwise be tedious and time-consuming, leaving them time to work on more pressing issues for the organization, such as business development. In another view, outsourcing of RPA, like other non-core businesses, can enhance organizational focus by about 50%.

Continuous Support and Maintenance: However, for the RPA application to gain an adequate amount of functionality, it has to be monitored, maintained, and updated over time. Another benefit of MSP is availability of workforce support on such tasks as this relieves internal IT and the business. However, the total availability of RPA services can be enhanced to the optimum level as some of RPA services providers have an availability of 99.9% in some cases.

Selecting the right partner is, therefore, essential when engaging in RPA services. Different organizations that provide RPA services are Accenture, Tata Consultancy Services (TCS), Suma Soft, Infosys, and Wipro. Assessing the competence, the years of experience and services they offered will assist before choosing the appropriate service provider that will meet the needs of your organization for the future automation plans.

3 notes

·

View notes

Text

Revolutionizing Construction: The Power of 3D Concrete Printing in Construction Technology

Introduction

In the ever-evolving landscape of construction technology, one innovation stands out as a game-changer: 3D concrete printing. This revolutionary technique is reshaping the way we approach construction projects, offering unprecedented speed, efficiency, and creative possibilities. In this article, we delve into the intricacies of 3D concrete printing and its profound impact on the construction industry.

Understanding 3D Concrete Printing

What is 3D Concrete Printing?

At its core, 3D concrete printing is a cutting-edge construction method that utilizes robotic arms or gantry systems to layer concrete in precise patterns, creating three-dimensional structures layer by layer. This departure from traditional construction methods not only accelerates the building process but also allows for intricate and customized designs that were previously challenging to achieve.

How Does it Work?

The process involves a blend of concrete, often enhanced with additives for improved strength and durability, being extruded through a nozzle in a controlled manner. The nozzle is guided by a computerized model, ensuring precision in the deposition of each layer. As the layers stack, a solid, fully functional structure emerges.

Advantages of 3D Concrete Printing

Speed and Efficiency

One of the most significant advantages of 3D concrete printing is its remarkable speed. Traditional construction methods can take months, if not years, to complete a project. In contrast, 3D printing can construct buildings in a matter of days or weeks, significantly reducing construction timelines.

Cost-Effective Construction

By minimizing material waste and accelerating the building process, 3D concrete printing translates into cost savings. The efficiency of this technology contributes to a reduction in labor costs and the overall expenses associated with traditional construction methods.

Design Freedom and Customization

Architects and builders now have unparalleled design freedom with 3D concrete printing. Complex and innovative architectural designs that were once impractical or prohibitively expensive can now be brought to life. This opens up new possibilities for creativity and customization in construction projects.

Applications of 3D Concrete Printing

Residential Construction

The residential construction sector is witnessing a surge in 3D-printed homes. From affordable housing projects to luxurious custom-designed residences, 3D concrete printing offers a versatile solution that aligns with various housing needs.

Infrastructure Projects

Large-scale infrastructure projects, such as bridges and tunnels, can benefit from the efficiency and precision of 3D concrete printing. The technology's ability to produce large and intricate structures with minimal manual intervention makes it an attractive choice for such endeavors.

Sustainable Construction

The environmental impact of traditional construction methods is a growing concern. 3D concrete printing addresses this by reducing material waste and incorporating sustainable concrete mixes. The result is a more eco-friendly construction process that aligns with global sustainability goals.

Challenges and Future Outlook

Technological Challenges

While 3D concrete printing holds immense promise, it is not without its challenges. Refinement in printing materials, addressing structural integrity concerns, and overcoming scale limitations are areas where ongoing research and development are crucial.

Future Prospects

As technology advances, we can anticipate further refinement and widespread adoption of 3D concrete printing. The integration of smart technologies, such as sensors and automation, will likely enhance the precision and capabilities of 3D printing systems, opening doors to even more ambitious construction projects.

Conclusion: Paving the Way for the Future

In conclusion, 3D concrete printing is more than just a technological advancement; it's a catalyst for change in the construction industry. Its ability to reshape the way we build, offering speed, cost-effectiveness, and design flexibility, positions it as a cornerstone for the future of construction. As the technology matures, we can expect 3D concrete printing to become an integral part of construction projects, defining a new era in the built environment.

3 notes

·

View notes

Text

How Digital Public Infrastructure is Revolutionizing Financial Inclusion in India

India’s rapid digital transformation has caught the world’s attention—not just in terms of tech innovation, but in how it has reshaped financial access for millions. The backbone of this change is India’s Digital Public Infrastructure (DPI): a stack of interoperable systems like Aadhaar, UPI, DigiLocker, and the Account Aggregator framework. Together, they’ve created a financial ecosystem that is inclusive, scalable, and data-rich.

But to truly harness the power of DPI, professionals need strong analytical capabilities. That’s where Certification Courses for Financial Analytics in Thane come into play—offering individuals the skillset to decode vast financial datasets and contribute to India’s inclusive growth story.

What Is Digital Public Infrastructure (DPI)?

Digital Public Infrastructure refers to core systems that facilitate identity, payments, and data exchange in an open, scalable, and secure way. India’s DPI includes:

Aadhaar – Biometric-based unique digital ID for over 1.3 billion people.

UPI (Unified Payments Interface) – A real-time payment system processing over 13 billion transactions monthly (as of May 2025).

DigiLocker – A cloud-based platform for issuing and verifying documents.

Account Aggregator – A consent-based data-sharing framework enabling individuals to share financial data securely.

Together, these form the foundation for delivering banking, insurance, credit, and welfare services across the socio-economic spectrum.

The DPI Impact on Financial Inclusion

✅ Banking the Unbanked

Over 500 million people have been brought into the formal banking system via Jan Dhan accounts linked to Aadhaar and mobile numbers. DPI has eliminated barriers like physical documentation and geographical access.

✅ Seamless Credit Access

With the Account Aggregator (AA) framework, lenders can now access verified financial data (with consent) to underwrite loans faster. This is revolutionizing credit access for MSMEs, gig workers, and rural entrepreneurs.

✅ Cost Reduction & Efficiency

Traditional banking and KYC costs have significantly dropped thanks to eKYC and digital documentation via DigiLocker, making financial services more affordable.

✅ Direct Benefit Transfers (DBT)

Government subsidies and welfare payments are now seamlessly deposited into beneficiary accounts through Aadhaar-based DBT, cutting out middlemen and leakage.

Why Financial Analytics Matters in DPI-Driven Finance

India’s DPI generates massive amounts of transactional and behavioral data every second. Banks, fintechs, NBFCs, and policymakers rely on financial analysts to make sense of this data and design effective, inclusive solutions.

Here’s how Certification Courses for Financial Analytics in Thane help bridge the gap:

Learn to work with UPI and AA datasets

Use tools like Python, SQL, Power BI, and Excel for data modeling

Understand financial inclusion metrics and risk scoring models

Apply statistical techniques to assess DPI’s impact on credit access or savings behavior

Train with case studies based on Indian financial systems

Use Cases: Analytics in Action

📊 Predicting Creditworthiness in Rural Lending

By analyzing income patterns from bank statements (via Account Aggregator), analysts can develop credit scoring models tailored for non-salaried borrowers.

📊 Optimizing DBT Programs

Government agencies use analytics to track whether welfare funds are reaching the intended beneficiaries, ensuring more efficient use of taxpayer resources.

📊 Fraud Detection in UPI Payments

Machine learning models help detect anomalies in UPI transaction patterns, flagging potential fraud and increasing trust in the system.

📊 Product Design for Financial Inclusion

Fintechs use location, behavior, and transaction data to create products like sachet insurance or micro-loans, tailored to low-income users.

Why Choose Certification Courses for Financial Analytics in Thane?

Thane, located near Mumbai—the financial capital of India—offers proximity to top banks, fintech companies, and startups. Choosing a financial analytics course in Thane gives learners access to:

Industry-Experienced Faculty: Learn from experts with hands-on experience in digital finance.

Live Projects & Internships: Apply learning to real-time DPI-related financial datasets.

Job Placement Support: Career services geared toward roles in analytics, risk, and product strategy.

Peer Learning: Interact with professionals from finance, data science, and public policy sectors.

Career Paths in DPI-Powered Finance

Role

Key Skills

Where You Fit In

Financial Data Analyst

SQL, Tableau, Python

Analyze trends in UPI usage, DBT effectiveness

Credit Analyst (AA Model)

Risk scoring, ML models

Design credit solutions for underserved segments

Policy Analyst

Statistics, policy understanding

Evaluate impact of DPI on financial inclusion

Product Analyst – Fintech

UX + Data

Build better digital banking products for Bharat

Conclusion: Building India’s Financial Future

India’s DPI is one of the most ambitious digital inclusion projects globally—and it’s working. But its true power lies in how well we use the data it generates to build more equitable financial systems.

By enrolling in Certification Courses for Financial Analytics in Thane, you gain the ability to turn raw data into real-world financial impact—improving access, reducing risk, and helping millions achieve financial stability.

0 notes

Text

Corrosion of Reinforcement Steel: Sustainability and Safety of Structural Members

Reinforcement corrosion protection illustrates the advanced safeguards put in place in modern construction to mitigate the deterioration of steel within concrete structures. Concrete is reinforced extensively across infrastructure such as buildings, bridges, tunnels, dams, and marine structures. Nevertheless, embedded steel reinforcements are susceptible to corrosion over time, particularly when subjected to harsh environmental conditions such as moisture, chlorides, and carbonation. This weakening results in cracking, spelling, and loss of structural integrity. To combat this adversity during both construction and maintenance phases, reinforcement corrosion protection strategies enable greater durability and extended service life for concrete structures.

Corrosion of reinforcement occurs from an electrochemical reaction involving water-oxygen interaction with chlorides or carbon dioxide. Steel typically enjoys protection due to a passive environment provided by concrete which consists of an alkaline environment resulting in a protective oxide layer on the steel surface. Loss of such shielding—due to the ingress of harmful agents (e.g., pH reduction)—initiates corrosion leading to rust that expands while causing surrounding concrete cracking and subsequently advancing structural disintegration.

There are multiple methods for reinforcement corrosion protection including the use of concrete admixtures that inhibit corrosion. These chemicals—like calcium nitrates or organic inhibitors—ensure the protective oxide film surrounding the steel is preserved and even reduces corrosion rates in aggressive environments.

Another significant approach is to coat the steel reinforcement section with protective coatings before it is embedded into concrete. Commonly used epoxy-coated rebar provides moisture and chloride barrier access, thus providing a physical barrier so that they cannot reach the surface of the steel. Steel reinforcements also galvanized whereby a layer of zinc is placed on them provide both inch terminal barrier protection along with sacrificial protection since zinc preferentially corrodes.

For structures that have already been constructed, corrosion progression can be delayed using surface-applied inhibitors and sealers designed to slow down corrosion. These materials diffuse into the concrete matrix maintaining alkaline conditions around steel or stop reagents from entering rusting sites. More sophisticated solutions such as reinforcing cathodic protection systems which applies low electric currents to steel to prevent ingress (corrosion), will also serve as advanced methodologies for reinforcement corrosion protection.

Increased cover depth for concrete, utilization of high-performance concrete with low permeability, and incorporating other cementations materials like silica fume or fly ash all help mitigate corrosion risk and support design practices aimed at protecting reinforcement corrosion.

Effective enhancement of reinforcement corrosion protection certainly comes with numerous advantages. For instance, it maintains the structural integrity, safety, and functionality of a given concrete asset throughout its life cycle. In addition, it minimizes the maintenance cost, the risk of vulnerability to uncontrolled damage or premature failure, and enhances sustainability by lengthening its service life while reducing replacement demands.

To summarize this discussion, reinforced corrosion protection is critical in preserving constructed reinforced concrete frameworks. Engineers are capable of lowering risks significantly through strategic amalgamations of material science, construction techniques, and rigorous maintenance plans. Furthermore, as the world’s infrastructure needs increase alongside environmental pressures, reinforced corrosion protection will forever be critical for ensuring safe structures that stand the test of time.

0 notes

Text

Metalens Market – Growth Outlook and Strategic Forecast

Metalenses are a revolutionary development in optical technology that use flat, nanostructured metasurfaces to precisely regulate light. In contrast to conventional multi-element lenses, metalenses substantially reduce size, weight, and complexity by utilizing an ultra-thin, single-layer architecture to accomplish complicated optical functions.

Thanks to developments in wafer-level nanoimprint lithography (NIL), which now enables high-volume, economical manufacture, the business landscape for metalenses is changing quickly. This scalability is opening up significant prospects in a variety of industries, from improved medical imaging equipment to LiDAR-enabled autonomous vehicles and incredibly small smartphone cameras. Metalenses have the potential to completely transform the design and implementation of optical components as the need for high-performance, compact optics grows.

Market Segmentation

By Application

Consumer Electronics: Largest segment, driven by smartphones, AR/VR headsets, and wearables. Metalenses replace bulky lens stacks, enabling thinner, lighter modules. Wafer-level NIL allows sub-$1 cost per lens at scale.

Healthcare & Medical Imaging: Ideal for compact devices like endoscopes, capsule cameras, and OCT probes. Metalenses offer high resolution in tight spaces and support biocompatibility for disposable use.

Automotive & LiDAR: Used in ADAS, LiDAR, HUDs, and in-cabin sensors. Metalenses reduce size, support 905/1,550 nm emitters, and enable polarization control.

By Wavelength

UV: <250 nm, for semiconductor and bioimaging; currently R&D-focused due to lithographic complexity.

Visible: 400–700 nm, dominates smartphone and AR optics, reducing lens stack height by >30%.

NIR: 850–1,550 nm, used in depth sensing, eye-tracking, and LiDAR.

By Region

North America: Strong R&D and defense/medical applications.

Europe: Growth in automotive and aerospace; innovation-led.

Asia-Pacific: Leading in volume production; rapid adoption in consumer tech and automotive.

Market Drivers

Electronic Device Miniaturization: The need for flat-optic solutions like metalenses is being driven by the growing demand for svelte and small consumer electronics, like as smartphones and AR/VR systems.

Improved Optical Performance for LiDAR and Sensing: Metalenses are perfect for high-performance sensing in cars and smart devices because of their exceptional beam steering, wavelength selectivity, and form factor reduction.

Improvements in Manufacturing Techniques: NIL advancements are enabling the commercial production of metalenses in huge quantities, thereby reducing the cost and entry barriers for widespread use.

Market Opportunities

Next-Gen Displays & Immersive Tech: Metalenses can dramatically reduce the optical stack in AR/VR and holographic systems, improving image clarity and supporting more ergonomic device designs.

Startup-Industry Collaborations: Market preparedness and commercial rollout are being accelerated by strategic alliances between semiconductor or optics heavyweights and metalens entrepreneurs.

Growth in Quantum and Photonic Computing: Metalenses are essential for quantum optics and next-generation photonic processors due to their exact shaping and polarization of light.

Market Restraints

High Complexity and Capital Requirements: High-precision lithography and sophisticated nanofabrication infrastructure are necessary for the production of metalenses, which presents a significant obstacle for small and emerging businesses.

Limited Global Fabrication Capacity: In the short term, a shortage of large-scale metasurface manufacturing facilities may limit supply, which would impede the growth of the entire market.

Key Market Participants

Metalenz

NIL Technology (NILT)

Lumotive

Jenoptik AG

Edmund Optics

SUSS MicroTec

Download Our Sample Report Now!

Get detailed information on Advanced Material Vertical. Click Here!

Conclusion

As companies look for small, effective optical systems for next-generation applications, the worldwide metalens market is expanding rapidly. Large-scale manufacturing is now feasible thanks to advancements in nanoimprint lithography, which has moved metalens technologies from research labs to commercial devices.

Strategic alliances, technology advancements, and growing demand in AR/VR, LiDAR, medical imaging, and quantum optics are driving significant market momentum, even though manufacturing complexity and capacity constraints still exist. Metalenses are anticipated to play a key role in the future of optical design as acceptance grows and manufacturing ramps up, revolutionizing industries ranging from consumer technology to healthcare and beyond.

0 notes

Text

Medical Endoscopes Market Outlook Current Status by Major Key Vendors and Trends by Forecast (2021–2031)

The medical endoscopes market size is expected to reach US$ 22,467.07 million by 2031 from US$ 14,487.23 million in 2024. The market is estimated to record a CAGR of 6.5% from 2025 to 2031.

Executive Summary and Global Market Analysis:

The global endoscopes market is experiencing robust growth, primarily spurred by the increasing adoption of minimally invasive diagnostic and therapeutic interventions. This expansion is significantly influenced by the rising global burden of chronic diseases and an aging demographic. Consequently, diverse medical fields, including gastroenterology, pulmonology, urology, and ENT, are progressively integrating advanced endoscopic techniques into their practices. Key technological advancements, such as high-definition imaging, the advent of disposable single-use endoscopes, and enhanced optical systems, are leading to improved procedural accuracy and a notable reduction in infection rates. Furthermore, the growing preference for outpatient and ambulatory care is amplifying the need for portable and cost-effective endoscopic solutions. Emerging markets are demonstrating impressive growth rates, underpinned by ongoing improvements in healthcare infrastructure and increasing public awareness of minimally invasive medical options.

Medical Endoscopes Market Drivers and Opportunities

The growing prevalence of chronic health conditions like digestive problems, respiratory issues, and cancer is creating a considerable need for sophisticated diagnostic tools. These conditions frequently necessitate regular and precise internal evaluations to monitor disease development and inform treatment choices. An endoscope is a vital medical instrument equipped with a light, used to visually inspect the inside of a body cavity or organ. This device is typically inserted through a natural opening, for example, the mouth during a bronchoscopy or the rectum for a sigmoidoscopy. As long-term health challenges affecting the gut, lungs, and urinary system become more common, medical practitioners are increasingly turning to endoscopic procedures for accurate diagnosis, efficient treatment delivery, and ongoing management of these health concerns.

Download our Sample PDF Report

@ https://www.businessmarketinsights.com/sample/BMIPUB00031632

Medical Endoscopes Market Segmentation

Medical Endoscopes Market By Product Type

Rigid Endoscopes

Flexible Endoscopes

Capsule Endoscopes

Ultrasound Endoscope

Robot-assisted Endoscopes

Medical Endoscopes Market By Usability

Reusable Endoscopes

Disposable Endoscopes

Medical Endoscopes Market By Application

Gastrointestinal Endoscopy

Laparoscopy

Gynecology Endoscopy

Arthroscopy

Uroscopy

Bronchoscopy

ENT Endoscopy

Neuroendoscopy

Medical Endoscopes Market By End User

Hospitals

Specialty Clinics

Ambulatory Surgical Centers

Diagnostic Centers

Medical Endoscopes Market Regions and Countries Covered

North America

US

Canada

Mexico

Europe

Germany

Italy

France

U.K.

Spain

Belgium

Netherlands

Luxembourg

Norway

Finland

Denmark

Sweden

Switzerland

Austria

Greece

Portugal

Russia

Poland

Romania

Czech Republic

Ukraine

Slovakia and Bulgaria

Asia-Pacific

China

Japan

South Korea

India

Australia

New Zealand

Indonesia

Malaysia

Philippines

Singapore

Thailand

Vietnam

Taiwan and Bangladesh

South and Central America

Brazil

Argentina

Chile

Colombia

and Peru

Middle East and Africa

Saudi Arabia

United Arab Emirates

Kuwait

Bahrain

Qatar

Oman

Turkiye

South Africa

Egypt

Nigeria and Algeria

Medical Endoscopes Market leaders and key company profiles

Olympus Corporation

Fujifilm Holdings Corporation

Boston Scientific

Karl Storz SE & Co. KG

Stryker Corporation

B. Braun SE

HOYA Corporation

Ambu A/S

Johnson & Johnson

Medtronic

About Us:

Business Market Insights is a market research platform that provides subscription service for industry and company reports. Our research team has extensive professional expertise in domains such as Electronics & Semiconductor; Aerospace & Defense; Automotive & Transportation; Energy & Power; Healthcare; Manufacturing & Construction; Food & Beverages; Chemicals & Materials; and Technology, Media, & Telecommunications

0 notes

Text

Regulatory Shifts Drive High-Performance Concrete Adoption

Concrete admixtures are materials added to concrete to improve workability, durability, and performance. In Europe and the CIS, the demand for these admixtures is surging, largely due to sustainability-driven regulations, urban redevelopment projects, and the need for resilient infrastructure in varying climates.

To Get Sample Report : https://www.datamintelligence.com/download-sample/concrete-admixture-market

Key Market Drivers

1. Green Construction Standards Europe’s Green Deal, LEED certifications, and strict VOC (Volatile Organic Compound) limitations are pushing builders toward eco-friendly admixtures. Governments are offering tax incentives and regulatory support for projects that use low-carbon concrete components.

2. Infrastructure Modernization in CIS Countries Russia and other CIS nations are investing heavily in large-scale transport, housing, and energy infrastructure projects. These require durable, fast-setting, and climate-resilient concrete, fueling the need for air-entraining agents, superplasticizers, and retarders.

3. Technological Advancements in Admixtures European manufacturers are innovating with digital-ready, self-healing concrete and polymer-based admixtures. These high-tech solutions offer strength, workability, and environmental advantages that meet the region's complex construction needs.

4. Rising Demand for High-Performance Construction Projects in regions with harsh climates require freeze-thaw-resistant, water-reducing, and set-modifying admixtures. Such products are gaining traction in Northern and Eastern Europe, especially in infrastructure and defense-related builds.

5. M&A and Strategic Collaborations Market players are consolidating to enhance portfolios and expand regional footprints. Multinationals are acquiring local firms to cater to country-specific admixture demand, particularly in niche and specialty product segments.

Regional Insights

Russia With a 17% share of the regional market, Russia is the largest consumer, fueled by state-funded infrastructure and industrial development. Cold-weather concreting techniques are vital, necessitating advanced admixture technologies.

Italy Italy has emerged as the fastest-growing market in Europe, thanks to strong government support for sustainable buildings and a push to modernize aging infrastructure. Growth in superplasticizers and shrinkage-reducing admixtures is notable.

Germany, UK, France, Spain These Western European countries are stable high-value markets, focusing on green-certified construction and urban densification projects. Adoption of eco admixtures and digital construction practices is leading the trend.

Eastern Europe and the Balkans Growth is being led by a boom in commercial and residential housing projects. The need for cost-effective and high-quality admixtures is significant here, with local manufacturers gaining traction.

Market Segmentation Trends

Superplasticizers: The largest and fastest-growing category, these offer water reduction and strength improvement.

Air-Entraining Agents: Crucial in cold climates like Scandinavia and Eastern Russia to prevent freeze-thaw damage.

Retarders and Accelerators: In demand for large-scale, complex projects where concrete setting time needs precise control.

Water Reducers and Shrinkage-Reducers: Growing in both developed and emerging CIS construction economies.

Growth Opportunities

Expansion in Eastern CIS & Balkans: Untapped urban areas, public housing, and industrial projects offer strong demand.

Smart Concrete Integration: Integration with sensors and digital monitoring systems offers high-value product evolution.

Sustainable Admixture Certification: Products aligned with green construction certifications are gaining preference.

Industry Trends

Growing R&D investment in bio-based and recycled admixtures

Use of nanotechnology and polymers for longer lifecycle and reduced maintenance

Adoption of admixtures with lower curing time for rapid infrastructure delivery

Final Outlook

With a projected value of over USD 10.6 billion by 2035, the Europe and CIS concrete admixture market is poised for strong, sustained growth. Green building norms, infrastructure evolution, and advanced admixture technologies are driving the sector forward. Industry leaders and innovators who embrace sustainability, digital integration, and region-specific solutions will define the next chapter in construction chemistry across Europe and the CIS.

0 notes

Text

Third Generation Advanced High Strength Steel Market Overview: Trends and Future Outlook

Introduction

The global Third Generation Advanced High Strength Steel Market is witnessing a transformative shift driven by the demands of lightweighting, safety, and fuel efficiency in key industries—especially automotive and transportation. As manufacturers seek alternatives to conventional steel without compromising structural integrity, third-generation AHSS is emerging as the material of choice. Combining the strength of first-generation AHSS with the ductility and cost-efficiency desired in modern applications, this market is poised for robust growth in the coming years.

Understanding Third Generation AHSS

Third-generation advanced high-strength steels (AHSS) represent the latest evolution in metallurgical innovation. They aim to provide:

High strength (above 1200 MPa)

Excellent ductility (over 20% elongation)

Enhanced formability

Improved crash energy absorption

Lower production cost compared to second-gen steels

These steels achieve superior properties by utilizing controlled alloying elements such as manganese, silicon, and aluminum, coupled with complex thermal and mechanical treatments like quenching and partitioning.

Key Market Trends

1. Rising Automotive Demand

The automotive industry continues to be the largest consumer of third-generation AHSS. Automakers are under constant pressure to reduce vehicle weight while maintaining or enhancing crash safety performance. This has accelerated the adoption of third-generation AHSS, particularly for components such as B-pillars, rocker panels, and bumper reinforcements.

2. Environmental Regulations and Emission Norms

Stricter emission norms globally are pushing manufacturers to reduce vehicle weight, thereby increasing fuel efficiency and lowering carbon dioxide emissions. Lightweight yet strong materials like third-generation AHSS help meet these objectives, reinforcing their importance in the market.

3. Electrification of Vehicles

The surge in electric vehicle (EV) production is another factor driving the Third Generation Advanced High Strength Steel Market. EVs require optimized body structures to compensate for the weight of batteries. AHSS offers an ideal solution, improving both safety and energy efficiency.

4. Material Innovation and Processing Advancements

Ongoing research into alloy composition and processing techniques, such as quenching and partitioning (Q&P) and medium manganese steels, is enabling better formability and cost control. These developments are making third-generation AHSS increasingly accessible across industries.

Future Outlook (2025–2032)

The Third Generation Advanced High Strength Steel Market is expected to grow significantly between 2025 and 2032, driven by:

Technological integration in automotive manufacturing

Infrastructure investment in emerging economies

Adoption in new sectors like construction, aerospace, and defense

Expansion of OEM partnerships and strategic collaborations

Market analysts anticipate a compound annual growth rate (CAGR) of 8–10%, with Asia-Pacific leading the demand, followed by North America and Europe.

Regional Market Insights

Asia-Pacific

Asia-Pacific, especially China, Japan, and South Korea, dominates the global market due to its large-scale automotive production, steel manufacturing infrastructure, and government policies supporting fuel efficiency and carbon reduction.

North America

North American growth is led by the U.S. and Canada, where auto giants are actively investing in vehicle electrification and crash safety technologies. Regulatory policies like the Corporate Average Fuel Economy (CAFE) standards further stimulate AHSS adoption.

Europe

Europe’s market is shaped by the European Green Deal and stringent CO₂ reduction goals. Automakers in Germany, France, and Italy are leveraging third-generation AHSS to meet lightweighting and recyclability goals.

Challenges in Market Expansion

Despite its potential, the Third Generation Advanced High Strength Steel Market faces several hurdles:

Complex processing requirements that demand new production techniques and capital investments

High initial costs compared to traditional steel grades

Limited skilled workforce familiar with AHSS stamping and welding processes

Supply chain vulnerabilities, particularly in sourcing rare alloying elements

Overcoming these challenges requires coordinated efforts between steelmakers, OEMs, and policymakers.

Competitive Landscape

Several key players are investing heavily in R&D and production capacity expansion to tap into the growing demand for third-generation AHSS. Leading market participants include:

ArcelorMittal

POSCO

SSAB

Tata Steel

United States Steel Corporation

AK Steel (Cleveland-Cliffs)

Voestalpine

These companies are forming strategic partnerships with automotive manufacturers and research institutions to create next-generation steel solutions tailored for advanced applications.

Conclusion

The Third Generation Advanced High Strength Steel Market is rapidly gaining momentum across automotive, construction, and industrial sectors. With its unique balance of strength, ductility, and cost-efficiency, third-generation AHSS is positioned as a cornerstone of future material strategies. As innovations in alloy design, processing techniques, and industry collaborations continue to advance, the market is expected to thrive—fueling a new era of lightweight, safe, and sustainable manufacturing.

0 notes

Text

High-Definition Body Sculpting in Kerala: Redefining Aesthetics and Wellness in God's Own Country

In recent years, the field of cosmetic and aesthetic surgery has undergone a transformation, thanks to remarkable innovations in medical technology and surgical techniques. Among the latest and most sought-after advancements is high-definition body sculpting, a cutting-edge procedure that has gained traction globally. Kerala, India's picturesque southern state known for its serene landscapes and holistic wellness culture, is emerging as a preferred destination for high-definition body sculpting in India.

At the forefront of this aesthetic revolution is the Sushrutha Institute of Plastic, Reconstructive & Aesthetic Surgery, located within the prestigious Elite Mission Hospital in Koorkenchery, Thrissur. Renowned for its excellence in cosmetic and reconstructive surgeries, the institute has become a beacon of trust for those seeking transformative, safe, and high-precision body sculpting solutions.

Understanding High-Definition Body Sculpting

High-definition body sculpting is an advanced form of liposuction that goes beyond traditional fat removal to reveal the underlying muscular anatomy. It is designed for individuals who are close to their ideal body weight but struggle with stubborn fat pockets that obscure muscle tone.

Using refined, precision-based techniques such as VASER (Vibration Amplification of Sound Energy at Resonance) and power-assisted liposuction, HD sculpting enables surgeons to accentuate natural muscle contours, resulting in a chiseled, athletic appearance.

Unlike standard liposuction, which primarily focuses on fat reduction, high-definition liposculpture aims to highlight and enhance areas such as:

Abdomen (six-pack sculpting)

Chest (pectoral definition)

Arms and shoulders

Thighs and glutes

Back and flanks

Why Choose High-Definition Body Sculpting in Kerala?

Kerala has long been a hub for traditional wellness practices such as Ayurveda and yoga, drawing medical tourists seeking holistic healing. Today, it combines this heritage with modern medical advancements to become a leader in aesthetic and plastic surgery.

Key reasons to choose Kerala for HD body sculpting include:

Affordable Yet World-Class Care:

Procedures in Kerala cost significantly less than in the U.S., Europe, or the Middle East.

Competitive pricing without compromising safety, hygiene, or results.

Internationally Trained Surgeons:

English-speaking, board-certified plastic surgeons trained in global centers.

Specialists in body contouring and HD liposuction.

Modern Infrastructure:

Hospitals like Elite Mission Hospital are ISO-certified and equipped with advanced surgical theaters, ICUs, and diagnostic facilities.

Peaceful Recovery Environment:

Kerala’s tranquil surroundings contribute to stress-free healing and post-op recovery.

Growing Reputation in Medical Tourism:

Increasing numbers of international patients are choosing Kerala for its blend of affordability, quality, and hospitality.

The Sushrutha Institute: A Benchmark in High-Definition Body Sculpting

Situated within the renowned Elite Mission Hospital, the Sushrutha Institute of Plastic, Reconstructive & Aesthetic Surgery in Thrissur is a top-tier facility dedicated to both aesthetic and reconstructive surgical care.

Core Strengths:

Board-certified plastic surgeons with international training.

Dedicated cosmetic surgery suites for privacy and safety.

Advanced tools for ultrasound-assisted and power-assisted liposuction.

Emphasis on natural-looking, sculpted results.

Customized treatment plans based on individual anatomy and aesthetic goals.

Whether you're seeking to sculpt your abs, contour your thighs, or define your chest, the institute’s specialists provide results that not only meet but often exceed expectations.

Benefits of High-Definition Liposculpture

Enhanced Muscle Definition

Reveals and accentuates natural musculature for a toned look.

Targeted Fat Removal

Eliminates stubborn fat in precise areas that resist diet and exercise.

Natural and Proportional Appearance

Tailored sculpting ensures harmony with your unique body shape.

Minimally Invasive with Minimal Scarring

Small, hidden incisions mean faster recovery and reduced scarring.

Boost in Confidence and Self-Esteem

A more defined physique can significantly enhance body image and mental well-being.

What to Expect: The Treatment Journey at Sushrutha Institute

Pre-Surgical Consultation

In-depth discussion with a plastic surgeon

Medical history assessment and aesthetic goals

Customized treatment planning and imaging

The Procedure

Typically performed under local or general anesthesia

Duration varies (2–4 hours depending on the number of areas treated)

Use of VASER or power-assisted liposuction devices

Post-Operative Recovery

Mild discomfort and swelling for the first few days

Compression garments are worn to aid healing

Return to light activity within a week

Visible results within 3–6 weeks, with continued improvement over 3–6 months

Other Services at Sushrutha Institute

Beyond high-definition body sculpting, the institute offers a full spectrum of aesthetic and reconstructive procedures:

Tummy Tuck (Abdominoplasty)

Gynecomastia Surgery (Male Breast Reduction)

Breast Augmentation and Lift

Rhinoplasty (Nose Reshaping)

Facial Rejuvenation (Facelifts, Blepharoplasty, etc.)

Fat Grafting & PRP Therapy

Scar Revision and Reconstructive Surgeries

Medical Tourism in Kerala: More Than Just Surgery

Kerala’s appeal extends beyond clinical care. Medical tourists can benefit from:

Ayurvedic wellness centers for holistic post-op recovery

Scenic locations for peaceful recuperation (beaches, backwaters, hills)

Cultural richness and hospitality that enhance the overall experience

The Sushrutha Institute offers concierge services for international patients, including visa assistance, airport transfers, and hotel or homestay coordination.

10 Frequently Asked Questions (FAQs)

1. What is high-definition body sculpting? It is an advanced liposuction technique aimed at enhancing muscle definition and creating an athletic physique by precisely removing fat from strategic areas.

2. Who is an ideal candidate for this procedure? Men and women who are near their ideal weight, have good skin elasticity, and want to enhance their natural muscle contours.

3. How is HD liposculpture different from traditional liposuction? While traditional liposuction removes fat to slim the body, HD sculpting uses precision techniques to reveal and define muscles for a more toned appearance.

4. Is the procedure painful? Mild discomfort and swelling are expected post-surgery, but pain is typically well-managed with medication and supportive garments.

5. What is the recovery time? Most patients resume light activity within 5–7 days. Full recovery, including visible muscle definition, can take 4–12 weeks.

6. Are results permanent? Yes, as long as the patient maintains a healthy lifestyle and stable weight. Fat cells removed during surgery do not return.

7. Can multiple areas be treated in one session? Yes, surgeons often treat the abdomen, chest, arms, and flanks in a single procedure, depending on the patient’s health and goals.

8. What are the risks involved? Like any surgical procedure, risks include bruising, swelling, temporary numbness, and rare complications like infection or contour irregularities.

9. How do I prepare for the surgery? Your surgeon will guide you through pre-op steps, including stopping certain medications, fasting, and arranging post-op care.

10. How do I book a consultation? You can book an in-person or virtual consultation via the Elite Mission Hospital website or directly contact the Sushrutha Institute through phone or email.

0 notes

Text

Tough & Light: Aramid Fiber Market Size, Share & Growth Analysis 2034 🛡️

Aramid Fiber Market is on a remarkable growth trajectory, expected to rise from $4.5 billion in 2024 to $9.2 billion by 2034 at a CAGR of 7.4%. Aramid fibers, known for their exceptional strength, heat resistance, and lightweight nature, are increasingly becoming a material of choice across various industries. From protective clothing in hazardous environments to components in high-performance vehicles and aerospace systems, aramid fibers offer durability and reliability where traditional materials fall short. This robust demand stems from an increasing need for advanced materials that deliver performance without compromising safety or sustainability.

Market Dynamics

Several factors are driving the dynamic growth of the aramid fiber market. On one hand, rising safety regulations and the push for durable, flame-retardant, and lightweight materials in sectors like defense, automotive, and aerospace are fueling demand. Para-aramid fibers, in particular, are highly sought after for their strength and heat resistance, dominating over 60% of the market share. Meta-aramid fibers, with their thermal stability, are also gaining popularity in filtration and insulation applications.

Click to Request a Sample of this Report for Additional Market Insights: https://www.globalinsightservices.com/request-sample/?id=GIS20293

Technological advancements in fiber production and weaving techniques have enabled manufacturers to optimize fiber properties for targeted applications. Moreover, the growing focus on sustainability is encouraging the development of bio-based and recycled aramid fibers. However, challenges such as high production costs, raw material availability, and competition from carbon and glass fibers remain significant hurdles for market players.

Key Players Analysis

The competitive landscape of the aramid fiber market is shaped by both legacy giants and emerging innovators. Industry leaders like DuPont, Teijin Limited, Kolon Industries, and Hyosung Corporation are continually investing in research and development to enhance fiber performance and reduce production costs. Collaborations with defense organizations, automotive manufacturers, and research institutions further solidify their market position.

Meanwhile, emerging companies like Aramid Edge, Fiber Guard Technologies, and Flexi Fiber Innovations are carving niches by offering customized and eco-friendly aramid solutions. The increasing inclination towards tailor-made fibers to suit specific industrial applications presents a unique opportunity for both established and new players.

Regional Analysis

Asia Pacific leads the global aramid fiber market, with China and India emerging as key contributors. This is largely attributed to growing automotive and defense sectors, coupled with infrastructure expansion that demands high-performance construction materials.

North America, particularly the United States, is a major hub for aramid fiber innovation, driven by its focus on aerospace, military-grade protective gear, and stringent safety regulations. Europe, led by Germany and France, showcases a strong preference for aramid fibers in automotive and telecommunications applications, supported by a strong push towards reducing emissions and improving fuel efficiency.

Latin America and the Middle East & Africa are slowly entering the fray, with Brazil, Mexico, and some Gulf countries leveraging aramid fibers in industrial and oil & gas sectors. However, challenges like regulatory constraints and economic volatility could impact the pace of growth in these regions.

Recent News & Developments

The aramid fiber market is experiencing significant technological and strategic transformations. Key players like DuPont and Teijin are developing newer production technologies aimed at cost reduction and environmental sustainability. Recent innovations include the commercialization of bio-based aramid fibers, which align with global sustainability goals without sacrificing strength or thermal resistance.

Pricing structures are seeing shifts due to raw material costs and production efficiency. Meanwhile, increased demand in electric vehicle manufacturing and renewable energy applications, such as wind turbines, is opening new doors for market expansion. Customization is another rising trend, with manufacturers offering industry-specific fiber variants, particularly in automotive and aerospace sectors.

Browse Full Report : https://www.globalinsightservices.com/reports/aramid-fiber-market/

Scope of the Report

This report provides a comprehensive analysis of the global aramid fiber market across multiple dimensions, including type, application, end-user, region, and form. It offers historical insights (2018–2023), current trends, and future projections (2025–2034) to help stakeholders make informed decisions. Key components include market drivers, restraints, opportunities, and threats, along with value chain analysis, SWOT evaluations, and PESTLE assessments.

With in-depth research backed by data from credible global agencies and government bodies, this report aims to provide a holistic view of market dynamics and competitive strategies. Whether you’re a manufacturer, investor, policymaker, or end-user, this market outlook serves as a valuable roadmap for navigating the evolving landscape of aramid fibers.

Discover Additional Market Insights from Global Insight Services:

Medical Packaging Films Market : https://www.globalinsightservices.com/reports/medical-packaging-films-market/

Cosmetic Packaging Market ; https://www.globalinsightservices.com/reports/cosmetic-packaging-market/

Concrete Admixtures Market : https://www.globalinsightservices.com/reports/concrete-admixtures-market/

Ethylene Glycol Market : https://www.globalinsightservices.com/reports/ethylene-glycol-market/

PVC Coated Woven Fabrics Market : https://www.globalinsightservices.com/reports/pvc-coated-woven-fabrics-market/

#aramidfibermarket #highperformancefibers #protectiveclothing #automotivetechnology #aerospaceinnovation #defensetechnology #sustainablematerials #fiberreinforcement #thermalresistance #advancedcomposites

About Us:

Global Insight Services (GIS) is a leading multi-industry market research firm headquartered in Delaware, US. We are committed to providing our clients with highest quality data, analysis, and tools to meet all their market research needs. With GIS, you can be assured of the quality of the deliverables, robust & transparent research methodology, and superior service.

Contact Us:

Global Insight Services LLC 16192, Coastal Highway, Lewes DE 19958 E-mail: [email protected] Phone: +1–833–761–1700 Website: https://www.globalinsightservices.com/

0 notes

Text

Role of Organic Waste Composter in Waste-to-Energy: Turning Scraps into Sustainable Power

In a world grappling with climate change, growing populations, and rising waste generation, sustainable solutions are the need of the hour. One such solution lies in Organic Waste Composters, which are not just waste treatment machines but key players in the broader Waste-to-Energy (WTE) ecosystem. These composters offer a clean, efficient, and eco-friendly way to convert organic waste into usable resources, including bioenergy.

🌱 What is an Organic Waste Composter?

A device or system that turns biodegradable waste, such as food scraps, agricultural wastes, and garden trash, into compost is called an organic waste composter. Through aerobic digestion, this waste is broken down into nutrient-rich compost that can be used to enrich soil. But beyond composting, these systems play a pivotal role in the waste-to-energy transition.

⚡ What is Waste-to-Energy (WTE)?

Waste-to-Energy refers to the process of generating energy in the form of electricity, heat, or fuel from waste materials. It includes a range of techniques such as anaerobic digestion, gasification, incineration, and fermentation. Organic waste is a significant input in many of these energy-generation processes.

🔄 How Organic Waste Composters Support Waste-to-Energy

While composters mainly convert waste into compost, they contribute to the WTE chain in multiple indirect and direct ways:

✅ 1. Pre-processing Organic Waste

The OWC composting machine helps segregate, stabilize, and reduce the volume of organic waste. Pre-treated compostable materials can then be further processed in anaerobic digesters or biogas plants to produce methane, which is burned to produce electricity or used as fuel.

✅ 2. Feedstock for Biogas Production

In integrated systems, organic composters work alongside biogas plants. Once initial composting reduces bulk and odors, remaining high-moisture content waste is diverted to anaerobic digestion, producing biogas and digestate (a semi-solid fertilizer).

✅ 3. Reduction of Waste to Landfill

By keeping organic waste out of landfills, the Waste Converter machine reduces methane emissions caused by uncontrolled anaerobic decomposition. This directly supports cleaner energy systems by lowering reliance on landfill gas capture and incineration.

✅ 4. Decentralized Energy Models

In rural areas and eco-villages, small-scale composters are paired with bio-digesters to create decentralized, low-cost bioenergy systems — powering cooking stoves, lamps, or even small electric grids.

🌍 Environmental and Economic Benefits

Benefit

Impact

♻️ Resource Recovery

Turns waste into compost or biogas

🌬️ Carbon Reduction

Cuts emissions from landfills and burning

💡 Energy Generation

Produces clean energy from food and organic waste

💰 Cost Savings

Reduces the need for synthetic fertilizers and fuels

🚮 Efficient Waste Management

Lowers pressure on urban waste systems

🏭 Industrial Use Case

Many large institutions (hotels, food processors, municipalities) use fully automatic organic waste composters as a first stage. The stabilized waste is then directed to anaerobic digesters to produce biogas, which fuels their operations, thus closing the loop between waste disposal and energy needs.

📌 Conclusion:

The OWC Machine is no longer just a backyard tool—it is an essential component of the Waste-to-Energy revolution. By bridging the gap between waste reduction and clean energy, it enables a circular economy where nothing goes to waste. Investing in composting infrastructure is not only good for the environment but also a strategic step towards energy independence and sustainable urban living.

0 notes

Text

How Do Data Engineering Consulting Services Help You Maximize ROI from Your Data?

Businesses today generate massive amounts of data but without a strategic approach, it often goes unutilized. Data engineering services help you build the technical backbone required to transform raw data into meaningful business insights. At Dataplatr, we create scalable data pipelines and architectures that ensure data is collected, processed, and stored efficiently, enabling faster and smarter decision making.

Why Are Expert Data Engineering Services Critical for ROI?

Investing in expert data engineering services ensures your data infrastructure is optimized for performance, scalability, and cost efficiency. Dataplatr’s experienced engineers design custom data workflows that eliminate redundancy, reduce manual intervention, and improve data accuracy. This leads to quicker insights and lower operational costs also boosting your return on every data investment.

What Makes Data Engineering Consulting Services a Smart Investment?

Data engineering consulting services provide the strategy needed to align your data infrastructure with business goals. Dataplatr works with your team to assess current systems, identify the problems, and implement future ready solutions. From cloud migration to real time analytics enablement, we help you achieve greater agility and competitive advantage.

How Do Data Engineering Consulting Firms Help You Unlock Hidden Value?

Partnering with leading data engineering consulting firms like Dataplatr gives you access to deep industry expertise and best practices. We help uncover hidden opportunities within your data, whether it's through better integration of siloed systems or advanced data transformation techniques. This unlocks new revenue streams, improves customer experiences, and enhances operational efficiency.

What ROI Benefits Can You Expect with Dataplatr’s Data Engineering Services?

With Dataplatr’s data engineering services, organizations often experience:

30–50% improvement in data pipeline performance

Significant cost reductions through cloud architecture

Faster go-to-market with real-time analytics solutions

Higher data trustworthiness for better decision making

Ready to Maximize ROI from Your Data Assets?

Partner with data engineering consulting services to modernize your data architecture, improve data quality, and reduce operational inefficiencies. The faster you act, the sooner you gain value.

0 notes

Text

Recycled Polyester Staple Fiber Market Gains Momentum Amid Global Push for Sustainable Textiles

The Recycled Polyester Staple Fiber Market is experiencing accelerated growth, driven by increasing environmental consciousness, government regulations favoring recycling initiatives, and the rising demand for sustainable materials in the textile and automotive industries. As the global textile sector pivots towards circular economy principles, recycled polyester staple fiber (RPSF) is emerging as a vital component in green manufacturing strategies.

Derived primarily from post-consumer PET bottles and industrial polyester waste, RPSF is widely used in applications such as apparel, home furnishings, automotive interiors, and non-woven fabrics. The material not only reduces dependency on virgin polyester but also offers significant environmental benefits including lower carbon emissions, energy savings, and landfill reduction.

According to recent analysis, the global Recycled Polyester Staple Fiber Market is projected to grow at a robust CAGR over the forecast period (2024–2032), with the market valuation expected to reach USD XX billion by 2032, underscoring its crucial role in shaping a more sustainable future.

Market Drivers

Rising Environmental Awareness: With growing concern over plastic pollution and climate change, consumers and manufacturers are increasingly adopting sustainable alternatives like RPSF.

Government and Regulatory Support: Policies promoting plastic recycling, textile waste reduction, and eco-labeling have significantly boosted the market’s adoption.

Increased Demand from Key Sectors: Apparel, automotive, and construction industries are actively integrating RPSF into their product lines to meet ESG targets and consumer expectations.

Explore in-depth data and growth trends here: https://dataintelo.com/request-sample/271810

Key Restraints

Quality Variability in Recycled Inputs: Inconsistency in raw material sources often affects fiber quality, limiting its application in high-performance products.

High Initial Processing Costs: While cost-effective in the long run, setting up RPSF manufacturing infrastructure can be capital-intensive.

Limited Consumer Awareness in Developing Regions: Despite global trends, many emerging markets still lag in terms of awareness and availability of sustainable alternatives.

Despite these hurdles, technological advancements in recycling processes and increasing government support are expected to mitigate these challenges, opening doors for wider RPSF adoption.

Emerging Opportunities

Circular Textile Economy: With a global shift toward closed-loop systems, RPSF presents enormous potential for textile brands aiming to create fully recyclable products.

Green Building Materials: The construction industry is adopting RPSF for insulation and geo-textile applications, offering new revenue streams.

Innovation in Blending Techniques: Advances in fiber blending are enhancing the performance of RPSF, enabling its use in high-end fashion and technical textiles.

Get exclusive access to growth opportunities and forecasts: https://dataintelo.com/report/recycled-polyester-staple-fiber-market-report

Market Dynamics and Growth Outlook

The Recycled Polyester Staple Fiber Market reflects a dynamic growth pattern influenced by changing consumer preferences, advancements in recycling technology, and global sustainability targets. North America and Europe are currently leading in market share due to stringent environmental policies and high awareness levels. Meanwhile, Asia-Pacific—particularly China and India—is witnessing exponential growth due to increasing investments in recycling infrastructure and rising domestic consumption.

Growth Trends:

Increase in demand for RPSF in fashion and fast retail brands

Technological innovations improving cost-efficiency and scalability

Rise in collaborations between recycling facilities and textile manufacturers

These trends indicate a positive long-term outlook, with the market poised to expand into diverse end-use segments.

Segmentation Overview

The Recycled Polyester Staple Fiber Market can be segmented based on origin, product type, application, and region:

By Origin:

Post-Consumer Waste (e.g., PET bottles)

Post-Industrial Waste (e.g., polyester fabric scraps)

By Product Type:

Hollow RPSF

Solid RPSF

By Application:

Apparel & Fashion

Automotive Interiors

Home Furnishings (e.g., mattresses, cushions)

Construction & Insulation

Non-Woven Fabrics (e.g., filters, wipes)

By Region:

North America

Europe

Asia Pacific

Latin America

Middle East & Africa

This granular segmentation helps identify lucrative opportunities and tailor strategies for different sectors and geographies.

Ready to analyze segmented data and regional trends? https://dataintelo.com/checkout/271810

Sustainability Impact and Industry Transformation

As organizations strive to meet net-zero carbon goals, RPSF is gaining traction as a preferred fiber alternative due to its significant environmental advantages. Key highlights include:

Reduction in Greenhouse Gas Emissions: Recycling PET into fibers emits up to 79% less carbon compared to virgin polyester production.

Water Conservation: RPSF manufacturing uses significantly less water than traditional textile production processes.

Waste Management Benefits: RPSF helps divert millions of PET bottles from landfills and oceans, contributing to better waste management systems.

Moreover, major textile certifications are increasingly recognizing RPSF-based products, thereby enhancing their credibility and market acceptance.

Global Market Forecast

The global Recycled Polyester Staple Fiber Market is expected to maintain a consistent growth trajectory, with a compound annual growth rate (CAGR) projected at X.X% from 2024 to 2032. Growth is anticipated across all regions, with Asia Pacific expected to dominate the volume share due to its vast textile manufacturing base and improving recycling capacities.

Key global dynamics shaping the forecast include:

Increasing investment in advanced recycling technologies

Expansion of green textile product portfolios

Rising demand for traceable and certified sustainable fibers

As sustainability becomes integral to business strategy, RPSF stands at the forefront of innovation, supporting a more responsible textile value chain.

Discover detailed market projections and investment insights: https://dataintelo.com/report/recycled-polyester-staple-fiber-market-report

Conclusion

The Recycled Polyester Staple Fiber Market is evolving rapidly, reflecting the broader shift towards sustainable consumption and production practices. With strong demand across multiple industries, proactive government support, and continuous technological innovation, RPSF is not just a trend—it is a transformative force in the textile and materials landscape.

Stakeholders including manufacturers, retailers, policymakers, and investors must align their strategies to harness the full potential of this eco-conscious market. As the global economy moves toward a greener future, RPSF offers a powerful solution that delivers both environmental and economic value.

0 notes

Text

Best Cosmetic Surgery Options for Face, Body & Skin

In today’s era of medical advancements and aesthetic awareness, cosmetic surgery has become a safe and effective way to enhance one’s appearance and boost self-confidence. Whether you're looking to rejuvenate your skin, sculpt your body, or refine facial features, choosing the right procedure—and the right hospital—is crucial. India is home to some of the most advanced and trusted plastic and cosmetic surgery hospitals, making it a top destination for both domestic and international patients.

In this blog, we’ll explore the best cosmetic surgery options for face, body, and skin, and help you understand how to choose the best plastic surgery hospital in India for your needs.

Best Cosmetic Surgery Options for the Face

The face is the most visible part of our identity, and many choose cosmetic surgery to refine or rejuvenate their facial appearance.

Popular Procedures:

Rhinoplasty (Nose Job): Reshapes the nose to improve appearance and function.

Facelift: Reduces sagging skin, wrinkles, and signs of aging.

Blepharoplasty (Eyelid Surgery): Enhances the appearance of the eyelids.

Chin and Cheek Implants: Adds definition and symmetry.

Botox and Fillers: Non-surgical options for wrinkle reduction and volume restoration.

Best Cosmetic Surgery Options for the Body

Cosmetic body surgeries aim to reshape or sculpt the body by removing excess fat or skin and improving proportions.

Popular Procedures:

Liposuction: Removes stubborn fat deposits from areas like thighs, abdomen, arms, and back.

Tummy Tuck (Abdominoplasty): Flattens the abdomen by removing excess fat and skin.

Breast Augmentation/Reduction/Lift: Enhances or corrects breast shape and size.

Mommy Makeover: Combines multiple surgeries to restore a woman’s post-pregnancy body.

Best Cosmetic Surgery Options for Skin

Your skin is a reflection of your health and age. Cosmetic skin treatments help reduce blemishes, scars, wrinkles, and pigmentation issues.

Popular Procedures:

Laser Skin Resurfacing: Improves skin tone, reduces scars, and removes wrinkles.

Chemical Peels: Treats pigmentation, sun damage, and uneven skin tone.

Microneedling with PRP: Stimulates collagen and rejuvenates dull skin.

Skin Tightening Procedures: Non-invasive treatments to firm sagging skin.

Choosing the Right Hospital for Cosmetic & Plastic Surgery

India has become a global hub for cosmetic and plastic surgeries due to its advanced medical infrastructure, affordable costs, and world-class surgeons. However, choosing the right facility is essential for safety and successful results.

When looking for the Best Cosmetic Surgery Hospital in India or the Best Plastic Surgery Hospital in India, consider the following:

Board-certified and experienced plastic surgeons

Accreditation and hygiene standards

Access to advanced equipment and techniques

Positive patient testimonials and results

Personalized pre- and post-operative care

If you're specifically searching for a trusted plastic surgery hospital in India or a reliable cosmetic surgery hospital in India, ensure they offer a wide range of procedures under expert supervision with patient-centric care.

Final Thoughts

Cosmetic surgery is a personal journey and should be approached with proper knowledge and careful planning. Whether you’re enhancing your facial features, sculpting your body, or refreshing your skin, India offers excellent options in both procedures and medical care. With the right information and the best cosmetic surgery hospital in India, you can safely achieve the look you desire and deserve.

0 notes